Vertical Honing Machine 1500 strokes

Product Details:

X

Product Description

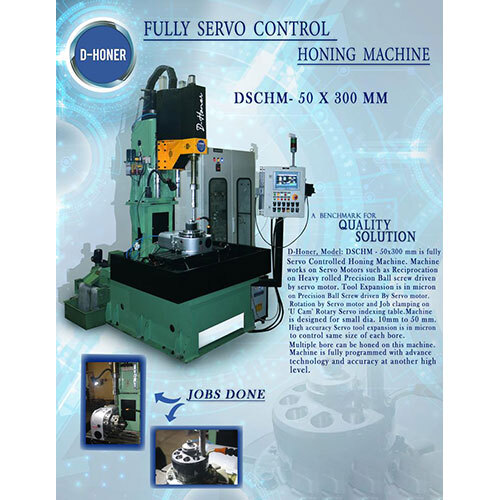

General Description:

- Honing Machine Type: Vertical honing machines are designed to work on parts held vertically, which helps maintain consistent pressure and tool contact throughout the honing process.

- Stroke Length (1500 mm): The "1500 stroke" specification means the honing tool can travel a maximum distance of 1500 mm, which is crucial for parts with long bores or larger internal diameters. This extended stroke allows the machine to finish the entire length of long, narrow parts like hydraulic cylinders, engine blocks, or other similar components.

- Tool Movement: The honing tool (abrasive stones or honing brushes) moves in and out along the workpiece under a controlled feed rate, ensuring that material is uniformly removed. It can operate on both rotating and reciprocating movements, depending on the machine design.

Key Components:

- Honing Head: Contains the abrasive stones or tools that perform the actual material removal. The head can be adjusted to accommodate various sizes and diameters of the workpiece.

- Vertical Spindle: This supports the honing head and enables vertical movement. The length of the spindle and the stroke (1500 mm) determines the range of parts it can handle.

- Feed Mechanism: Controls the axial movement of the honing tool, ensuring consistent pressure and uniform material removal during the honing process.

- Workpiece Holding System: In vertical honing machines, the workpiece is held in place by chucks or fixtures, which are adjustable to handle a wide range of part sizes and shapes.

- Control Panel: Typically, vertical honing machines feature advanced control systems that allow operators to adjust feed rates, stroke lengths, and tool pressures, ensuring precision and consistent quality.

Applications:

- Automotive Industry: Finishing engine cylinders, transmission parts, and other critical internal components.

- Aerospace: Precision honing of bores in aerospace components like fuel nozzles or hydraulic cylinders.

- Hydraulic & Pneumatic Systems: Honing cylinder bores for hydraulic pistons and other parts that require smooth, accurate internal surfaces.

- General Manufacturing: Finishing parts requiring high surface quality and exact dimensional tolerances.

Advantages:

- Precision Finishing: Provides superior surface finishes, essential for parts that need tight tolerances and smooth internal surfaces.

- Versatility: Can handle parts of varying lengths and sizes, especially with a stroke length as long as 1500 mm.

- Efficient Material Removal: The machine can remove material gradually, reducing the risk of tool damage and heat buildup in the workpiece.

Considerations:

- Size of Workpieces: With a 1500 mm stroke, the machine is suited for larger components or those with long, internal bores. It might not be suitable for smaller, short-length parts.

- Speed and Feed Control: Precise control of speed, feed rates, and tool pressure is essential to avoid surface defects, tool wear, or improper material removal.

In short, a vertical honing machine with a 1500 mm stroke is a robust, precise tool designed for finishing larger workpieces with long internal bores, ensuring smooth surfaces and dimensional accuracy in a variety of industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese